The Industrial Beast: Why CO2 Systems Are Still Unbeatable (And How to Install Them Safely)

If you’re running a power plant, a printing press, or a heavy manufacturing facility in Saudi Arabia, you don’t need “gentle” fire protection.

You need a beast.

When it comes to high-hazard industrial environments, there is one king that has ruled for over a century: The CO2 Fire Suppression System.

But here is the catch. CO2 is incredibly powerful, but if it’s installed by amateurs, it’s dangerous.

Today, I’m going to show you why CO2 is the ultimate industrial solution and why Advanced Systems is the partner you need to harness this power without risking your team’s safety.

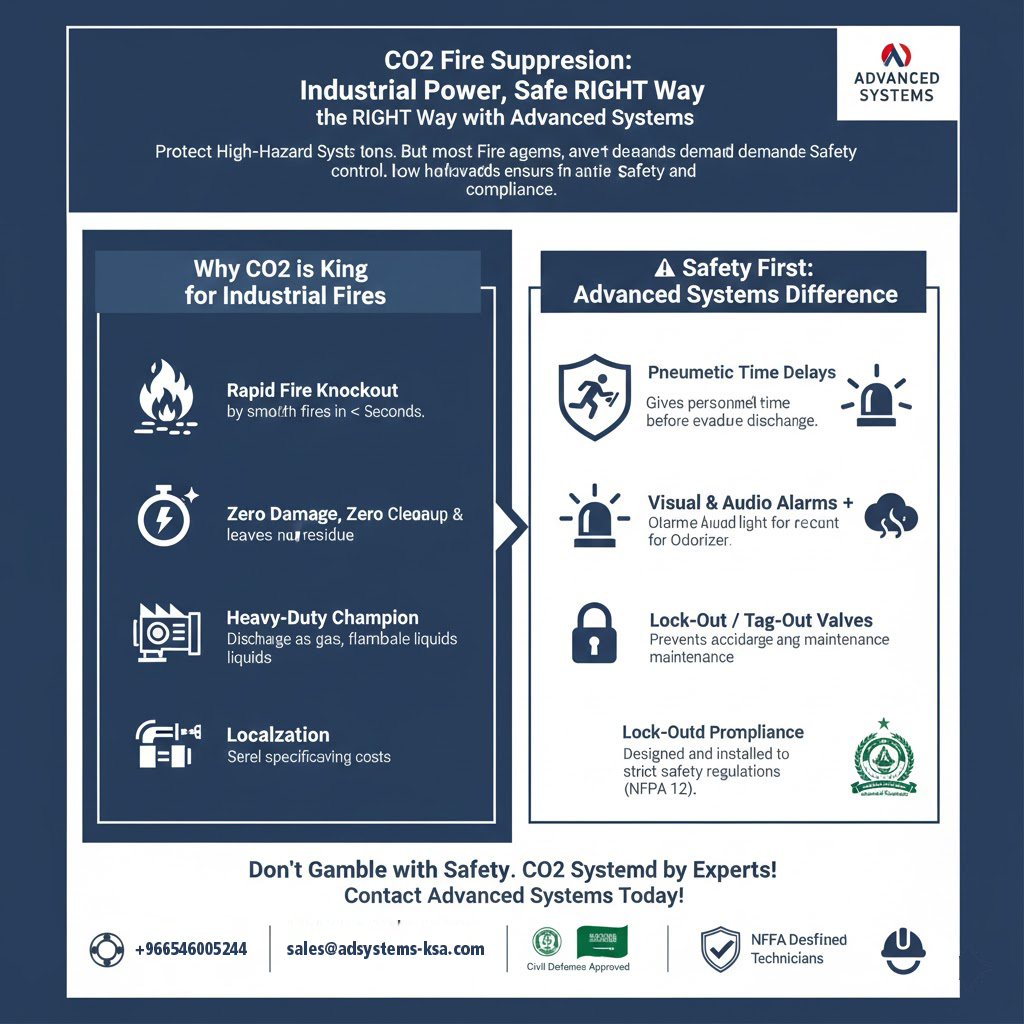

Why CO2 is the “Heavyweight Champion” of Fire Suppression

Unlike Novec or FM-200, which are often used for delicate electronics, CO2 is built for aggressive fire fighting.

Here is why it’s still the top choice for industrial giants:

-

Total Oxygen Displacement: CO2 doesn’t just “cool” the fire; it suffocates it. By rapidly reducing oxygen levels, it kills the fire instantly.

-

Zero Residue, Zero Cleanup: Even though it’s “heavy-duty,” it’s still a gas. No foam, no water, no mess. You can restart your heavy machinery immediately after the system is cleared.

-

Local Application Expert: CO2 is unique because it can be used for “Local Application.” If you have one specific high-risk machine in a large factory, you can design the system to protect just that spot instead of flooding the whole building.

-

Cost-Effective Refills: CO2 is widely available and cheap to refill. For large-scale industrial sites, this makes it the most economical long-term choice.

The Danger Factor: Why You Can’t Cut Corners

I have to be honest with you. CO2 works by removing oxygen. That means it’s lethal to humans if they are in the room during discharge.

This is why you CANNOT hire a “cheap” contractor.

In Saudi Arabia, the Civil Defense has zero tolerance for safety violations regarding CO2. When you work with Advanced Systems, they build in “Safety-First” protocols that most others ignore:

-

Pneumatic Time Delays: To give everyone time to exit before discharge.

-

Warning Sirens & Odorizers: Adding a scent to the CO2 so people can “smell” the danger.

-

Lock-out Valves: To ensure the system doesn’t accidentally fire during routine maintenance.

[Image suggestion: Industrial machine room protected by CO2 nozzles]

Why Advanced Systems is the “Gold Standard” for CO2 in KSA

Advanced Systems doesn’t just “install pipes.” They engineer failsafe environments.

1. Expert Industrial Design

Whether it’s a “Total Flooding” for an unmanned engine room or a “Local Application” for a dip tank, their engineers calculate the exact CO2 concentration required by NFPA 12 and Saudi Civil Defense standards.

2. Civil Defense Approval (The “Green Light”)

Obtaining a permit for a CO2 system is tough. The authorities want to see perfect safety measures. Advanced Systems handles the entire approval process, ensuring your facility is 100% compliant with local laws.

3. Rigorous Maintenance

CO2 systems operate under high pressure. One loose fitting can be a disaster. Advanced Systems provides a maintenance schedule that includes hydrostatic testing and weight checks to ensure your cylinders are ready for action 24/7.

Conclusion: Power Requires Control

If your business involves flammable liquids, power generators, or large industrial machinery, CO2 is your best friend. But it’s a friend that needs to be handled with expert care.

Don’t gamble with human lives or your industrial assets.

Choose the system that works, and choose the company that knows how to make it safe.

Contact Advanced Systems today. Let’s protect your facility with the power of CO2—the right way.